DISTRIBUTION CENTER

Discover The State of the Art Technology, Materials and Software Critical for Today’s Dental Professional…

We believe the equipment we sell is truly best in class. We only put our reputation with the best equipment that the industry has to offer. Our Distribution Center only sells equipment which we use everyday in our Laboratory, Education Center, and Practices.

The Most Advanced Technology Today

Here at Esthetic Professionals Dental Distribution Center, we proudly offer 3D printers, CBCTs, Intraoral Scanners, Software, Materials & more!

Meet the Future

of Digital Dentistry

Precise. Efficient. Faster Production.

VHF has the mill for you.

Print Same-Day Clear Aligners

We are a proud distributor of the innovative technology produced by LuxCreo. Meet iLuxPro Dental, the first printer in the country to print clear aligners in your practice, same day.

Software Is Where It All Begins

Whether you are looking to design chairside, or in the laboratory, we have the Software for you. Software to design crown & bridge, implants, removables, bars, temporaries, and even smile design. We have the CAD and CAM software for all your designing needs.

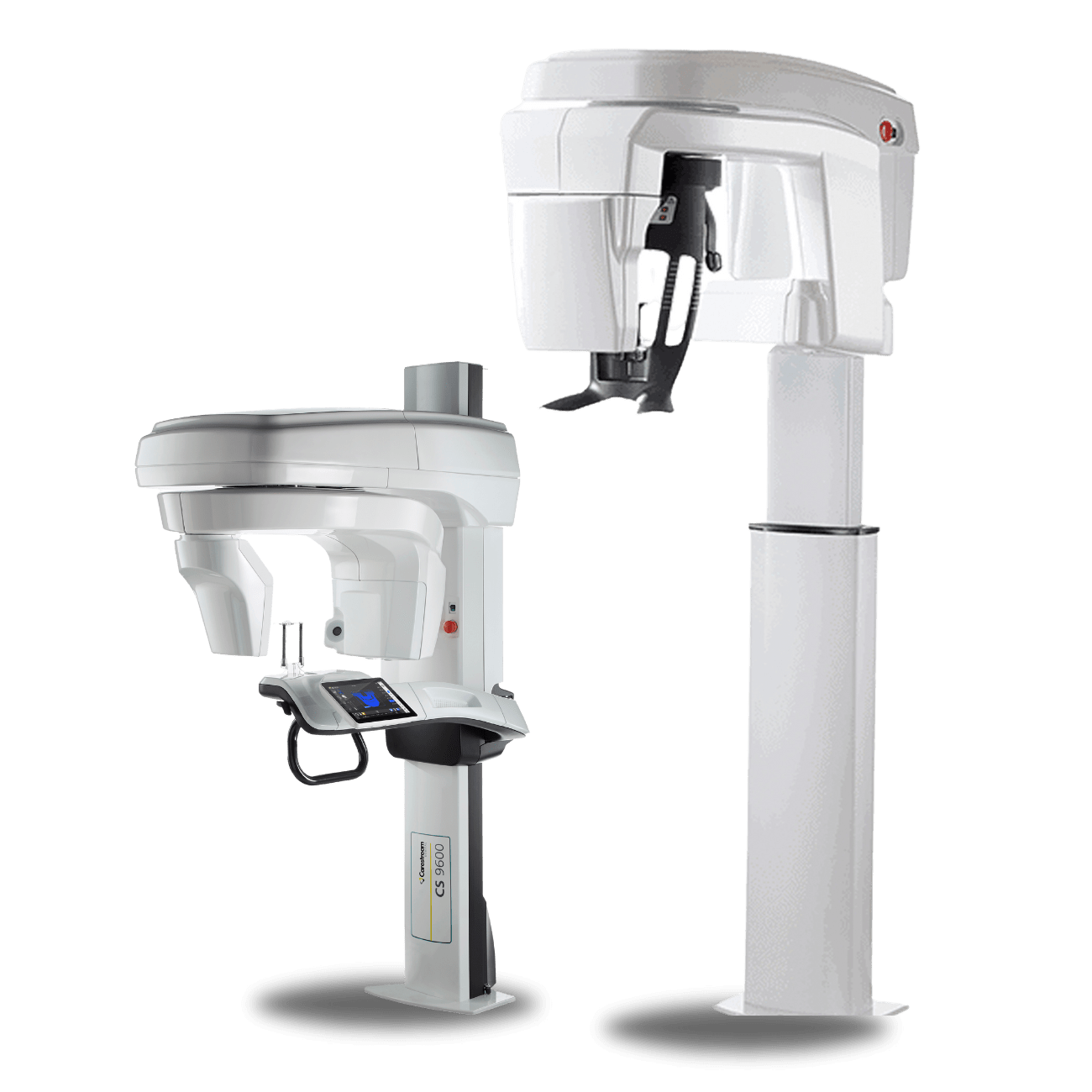

Upgrade The Way You Diagnose

Carestream CBCTs and accessories: We carry some of the most advanced 2D/3D digital imaging systems on the dental market, upgrade your practice with this award-winning technology.

From A to Zirconia We’ve Got You Covered

The materials we sell have been used by our Doctors and our Laboratory Technicians extensively. We are able to discuss Indications, Strengths, Applications, Composition and a wide array of other information for each material sold. Just ask us. . .

Distribution form

"*" indicates required fields

Our Valued Customers

All of us at Esthetic Professionals Distribution truly value all of our hard working and talented professionals. We take pride in the fact that they have chosen us to be their partner on this digital journey. We want to thank all of you, and we look forward to supporting you in any way we can.

“All of us here at Blossom Dental would like to thank Bob for all his help in the training this week. We do appreciate him being here for us. We also want to say thanks to all for the support we have already gotten and I’m sure what is to come. Hope everyone has a great weekend.”

“I speak from personal experience, the Motion 2 is the best wet/dry mill on the market, and Esthetic Professionals are the only distributor you should buy it from. If you have any questions please feel free to contact me at my office.”

“You won’t believe this. I just received a gift set of wine, with your name on it! One bottle for me, and one for my wife, Kim! How thoughtful! Veronica called the other day to introduce herself. I’m beginning to feel I really made the right choice for a company to do business with.

Address

18981 Ventura Blvd

Tarzana, CA 91356

Call Us

Dental Practice 818.654.7100

Laboratory 818.654.7101

Education Center 818.654.7102

Distribution Center 818.654.7069

Email Us

practice@estheticprofessionals.com

education@estheticprofessionals.com

laboratory@estheticprofessionals.com

distribution@estheticprofessionals.com