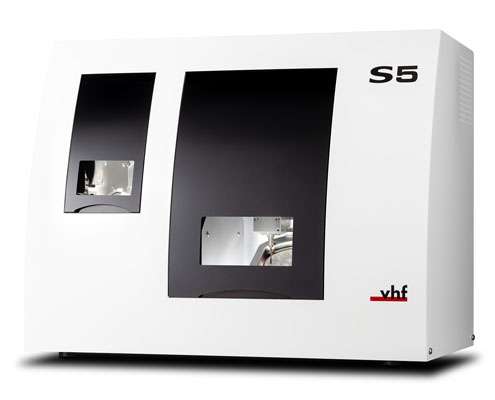

S5. Top-performance. Nonstop.

5 Axes | 8 Discs | 24 Block | 16 Tools

Uses no compressed air; offers both dry-milling of discs and blocks.

- Enhanced with an eightfold material changer for discs, blocks, and abutments for automation.

- Features an extra-large liquid tank for prolonged wet processing durability.

- Equipped with built-in ionizers to significantly reduce cleaning efforts for dry processing.

The S5 dental milling machine is exceptionally versatile, equipped with five axes that operate simultaneously. It features a blank changer capable of holding eight blanks and is suitable for both dry and wet machining. Additionally, with the optional wet grinding module, you can grind various types of glass ceramic materials.

- Dry and wet machining

- Materials: Plastic materials, wax, zirconia, composites, CoCr, model plaster, glass ceramics, titanium

- Discs, height 10–30 mm (metals up to 18 mm), diameter 98.5 mm

- Blocks up to 45 × 20 × 20 mm

- Indications Crowns, bridges, fully anatomical crowns and bridges, inlays, onlays, abutments, telescopic crowns, models, model castings, bite

splints, implant bars, veneers, drilling templates, dentures, table tops etc.

BASE SYSTEM

Construction

Machine bed made of solid cast aluminum body

Housing

Sheet steel housing, white high-gloss lacquer finish with working chamber flap and material changer flap

Number of axes 5

Linear axes

X-/Y-/Z-axis

Precision ball screws · motors with resolution < 1 μm · ground precision guides made of high-alloyed steel · repetition accuracy

± 0.003 mm

Rotary axis

Backlash-free Harmonic-Drive® with highest concentricity · rotation angle: 360°, infinite

Control Unit

5-axis simultaneous control electronics with continuous path progression and dynamic pre-calculation · hardware-based real-time operating system with standardized command set · FPGA-integrated processor · updateable hardware · real-time path calculation via

hardware engines in the FPGA · four-quadrant control of the motors for particularly smooth running · multiple analogue and digital I/

Os for co

Lighting

RGB LED lighting with status display in the working chamber and in the blank changer

Sophisticated

- QuickFrame magnetic holder enables easy, tool-free clamping of discs (one piece included).

- Simple operation through DENTAL CAM software with DIRECT MILL Technology, provided without license fees.

- Extensive material options available in 98mm disc format, around 40 block materials, and over 800 prefabricated titanium and CoCr abutment blanks.

- Wide range of applications with up to ±30° rotation angle in the 5th axis and up to 30mm blanks.

- Three ionizers eliminate static charge on acrylic chips to maintain a clean working environment.

- Optional wet-grinding module transforms the S5 into a wet-processing machine.

- A spindle equipped with water cooling ensures excellent outcomes, even during continuous use.

Precise

- Ultra HD Restorations

- Equipped with a premium spindle featuring precision bearing, a robust 600 watts, and 60,000 rpm

- Achieves 3 μm repetition accuracy

- Continuous milling and grinding facilitated by an automatic changer for 8 discs, 24 blocks, or 48 prefabricated abutments

- Automatic tool changer for 16 tools

Reliable

- Ultra HD Restorations

- Equipped with a premium spindle featuring precision bearing, a robust 600 watts, and 60,000 rpm

- Achieves 3 μm repetition accuracy

- Continuous milling and grinding facilitated by an automatic changer for 8 discs, 24 blocks, or 48 prefabricated abutments

- Automatic tool changer for 16 tools

- Capable of processing all kinds of materials, such as CoCr, titanium, and glass-ceramic

- Features a solid cast body to minimize vibrations